Industrial and warehouse facilities don’t have the luxury of disruption. When cleaning interferes with workflows, creates safety risks, or requires constant oversight, it becomes a problem instead of a support function.

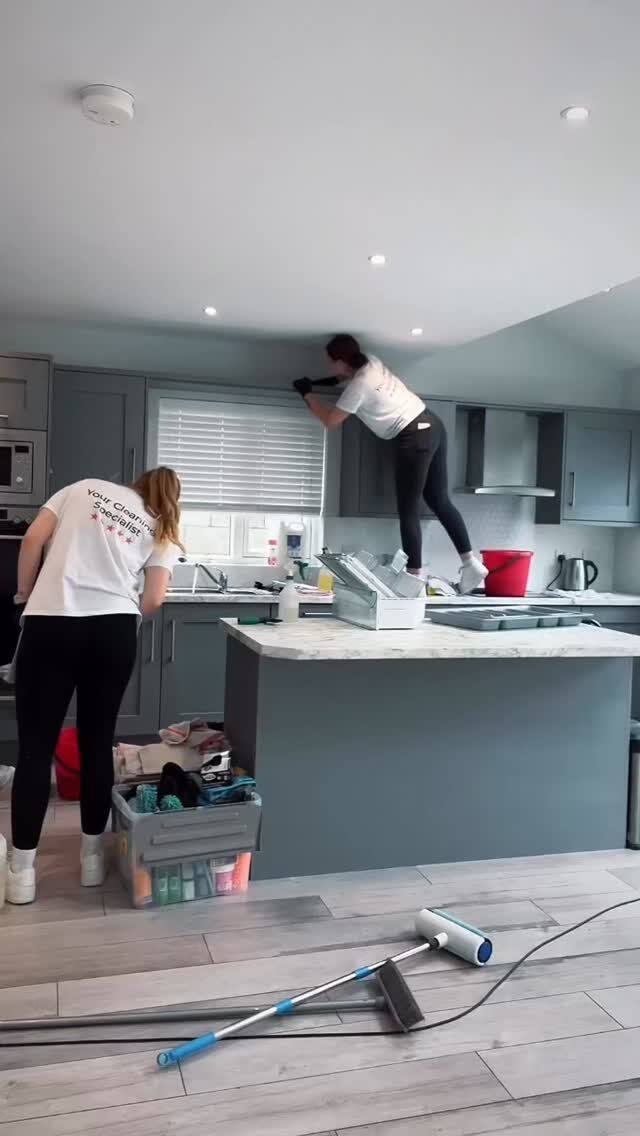

This industrial & warehouse cleaning service in Dublin is built for facilities that need clean, safe, and organised environments without slowing operations down. The focus is on maintaining clear access routes, reducing hazards, and keeping large operational spaces running smoothly — so teams can work efficiently and managers aren’t pulled into day-to-day cleaning issues.

The same structured systems used in our office cleaning services are applied to industrial and warehouse environments to ensure consistency and accountability.

In industrial and warehouse environments, cleaning is only “invisible” when it’s done properly. When it isn’t, the impact is felt immediately — blocked access routes, dusty work zones, safety concerns, and teams working around problems that shouldn’t exist in the first place.

Most facilities don’t struggle because they aren’t cleaned often enough. They struggle because cleaning:

Over time, this leads to unnecessary risk, distraction, and downtime. Instead of supporting operations, cleaning becomes another variable that needs managing — which is the opposite of what a professional industrial environment needs.

The right approach keeps facilities safe, organised, and operational, without pulling attention away from the work that actually matters.

Industrial and warehouse environments don’t operate like offices — and they can’t be cleaned like them either. These spaces are built around movement, machinery, and volume, with workflows that leave little room for interruption.

They typically involve:

In this context, cleaning needs to be planned, not improvised. Timing, access, and consistency matter just as much as the clean itself. A suitable service understands how the site operates and works around it — maintaining standards without slowing teams down or creating new obstacles.

This is why industrial and warehouse cleaning must be structured, predictable, and aligned with operational flow — not treated as a generic add-on.

Clear access routes, cleaner floors, and reduced build-up in high-traffic zones help lower slip, trip, and safety risks — supporting a safer day-to-day working environment for staff and visitors.

Cleaning is planned around workflows, shifts, and site activity so teams aren’t forced to work around cleaning or adjust schedules to accommodate it.

The same level of cleanliness is maintained visit after visit, removing the frustration of “good days and bad days” depending on who attends or how busy the site is.

With predictable routines and clear scope, managers aren’t pulled into chasing standards, reporting missed areas, or coordinating fixes during operational hours.

A consistently clean and organised facility supports internal checks, external audits, and site walk-throughs without last-minute scrambling or reactive clean-ups.

Clean, well-maintained industrial environments reflect operational control and professionalism — helping facilities run more smoothly and present better to staff, contractors, and stakeholders.

Industrial & warehouse cleaning works best when it’s aligned with how a site actually operates. This service is designed for facilities where cleaning needs to support safety, flow, and continuity — not interrupt them.

Being clear about suitability upfront helps avoid disruption, mismatched expectations, and wasted time on both sides.

In industrial and warehouse environments, cleaning problems don’t stay hidden. When standards slip or routines aren’t aligned with operations, the consequences show up quickly — often at the worst possible time.

A structured industrial & warehouse cleaning service helps prevent:

Build-up on floors, access routes, and shared areas increases slip, trip, and collision risks in high-traffic environments.

Poorly timed or reactive cleaning forces teams to work around obstacles, slowing productivity and creating frustration.

Without structure, results vary depending on the day or person on site, leading to uncertainty and missed areas.

Facilities end up reacting instead of operating with control when cleanliness hasn’t been maintained consistently.

Time is lost chasing issues, reporting problems, or arranging corrective cleans during operational hours.

A visibly unorganised or poorly maintained facility reflects a lack of control — something stakeholders and inspectors notice immediately.

Preventing these issues keeps facilities safer, smoother, and easier to manage day to day.

Industrial and warehouse cleaning is structured around how facilities are used, not a generic checklist. Coverage is aligned with layout, traffic flow, and operational priorities to ensure the areas that matter most are consistently maintained.

Typical coverage includes:

Floors are cleaned with attention to walkways, loading paths, and shared routes used throughout the day, helping maintain safe and clear movement across the site.

Areas with regular footfall, equipment movement, or repeated use receive focused attention to reduce build-up and risk.

Cleaning is carried out around storage systems and open working areas without interfering with layout or operations.

High-use zones that impact daily logistics and site presentation are maintained as part of the routine.

Break areas, washrooms, and shared facilities are cleaned to support staff wellbeing and site standards

Handles, switches, rails, and shared contact points are addressed to maintain hygiene consistency across the facility.

The exact scope is always matched to how the facility operates, ensuring coverage supports safety, flow, and continuity rather than disrupting them.

Our industrial cleaning processes are designed to support recognised occupational health and safety standards in active warehouse environments.

Industrial & warehouse cleaning is designed to maintain clean, safe, and functional operational environments. It’s important to be clear about what falls outside the scope so expectations stay aligned and risk is avoided.

This service does not include:

Being clear about boundaries ensures the service matches the facility properly, protects operational safety, and avoids unnecessary disruption or misunderstanding.

Industrial facilities don’t need promises — they need predictability. Cleaning works best when it follows a clear process that fits around operations and produces the same standard every visit.

This service is delivered through a structured approach:

Layout, traffic flow, shift patterns, and safety-critical areas are considered so cleaning aligns with how the site actually operates.

Cleaning is planned to avoid disruption, whether that means working around shifts, quieter periods, or specific access windows.

A structured routine is followed to ensure high-traffic and safety-sensitive areas are covered consistently, not selectively.

Attention is given to the areas that affect movement, access, and day-to-day site function rather than cosmetic details alone.

The same standard is maintained visit after visit, removing uncertainty and reducing the need for oversight.

This process keeps cleaning controlled, reliable, and aligned with operational demands — so facilities stay clean without becoming harder to manage.

For sites that need a full reset before inspections, audits or handover, this is typically achieved through our deep cleaning services.

This industrial & warehouse cleaning service is delivered exclusively to facilities operating in Dublin and surrounding industrial areas. Local coverage allows cleaning to be scheduled reliably, aligned with site access requirements, and supported without delay.

Facilities supported across Dublin include:

Focusing on Dublin-based facilities ensures the service remains consistent, responsive, and aligned with local operational expectations — rather than stretched thin across distant locations.

No. Industrial & warehouse cleaning focuses on operational spaces, safety-critical areas, and high-traffic zones. It differs significantly from office or general commercial cleaning, which is not structured for scale or industrial use.

This service is intended for ongoing, recurring cleaning. One-off or post-incident cleaning is assessed separately to ensure the correct scope and approach.

Pricing is based on facility size, layout, cleaning frequency, access requirements, and operational constraints. Quotes are provided after understanding how the site operates to ensure accurate, fair pricing.

This service is best suited for warehouses, logistics facilities, industrial units, distribution centres, and manufacturing support areas where cleanliness affects safety and efficiency.

Cleaning frequency depends on foot traffic, type of operation, and safety requirements. Many warehouses require daily or multiple weekly cleaning, while others operate on structured weekly schedules. The right frequency is based on how the facility is used, not a generic package.

Yes. Industrial cleaning is typically scheduled around shift patterns, quieter periods, or defined access windows so operations can continue without disruption.

Yes. This service is designed specifically for large-scale industrial and warehouse environments, where consistency across wide floor areas and access routes is essential.

In industrial and warehouse environments, cleaning should never interfere with productivity. When it’s planned properly, it runs quietly in the background — keeping work areas safe, access routes clear, and standards consistent without pulling attention away from operations.

If you need industrial & warehouse cleaning in Dublin that supports safety, continuity, and day-to-day efficiency, this service is built for that purpose.

Our structured approach is also relied on for corporate and tech office cleaning in Dublin, where consistency, presentation and accountability are non-negotiable.